Pressure-sensitive tape is a type of adhesive tape that adheres to surfaces upon the application of pressure, without the need for water, heat, or solvent-based activation. It's designed to stick to surfaces with just the application of hand or finger pressure. This type of tape is commonly used in a variety of applications, ranging from packaging and sealing to arts and crafts.

The tape is composed of three main components:

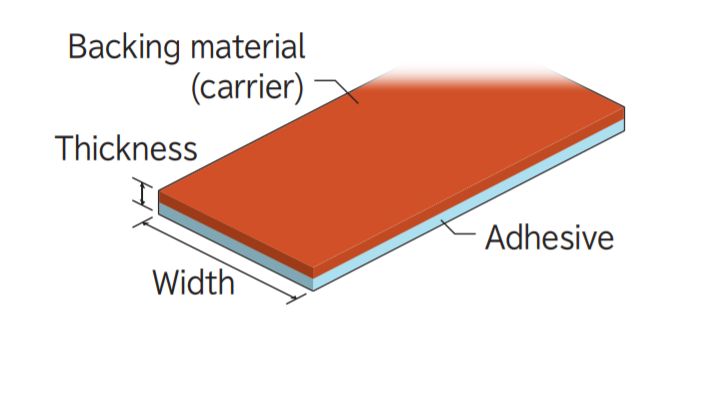

Backing Material: This is the physical structure of the tape that provides it with strength and durability. The backing can be made from materials like paper, plastic, fabric, or foil.

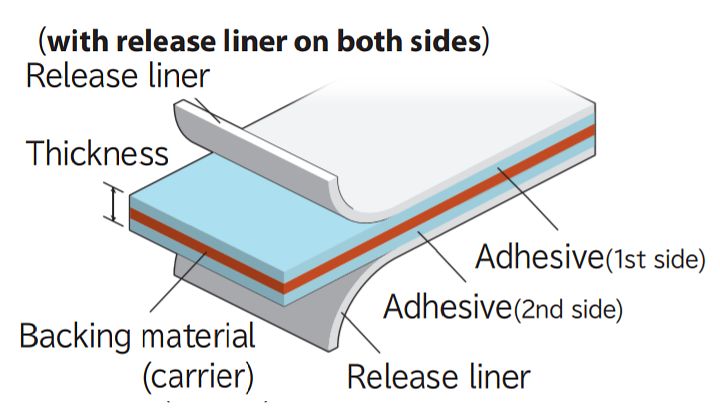

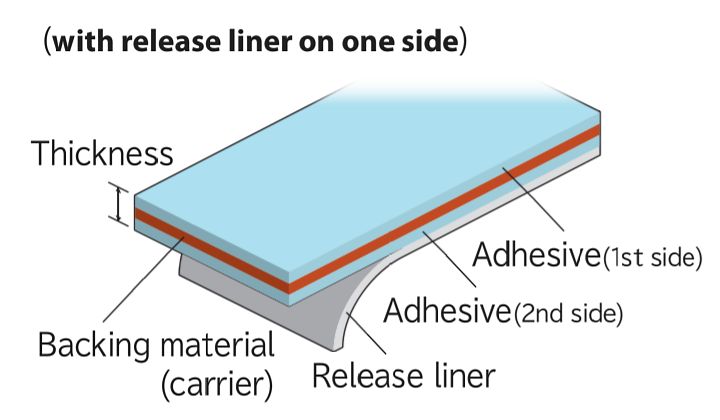

Adhesive Layer: The adhesive layer is the substance that allows the tape to stick to surfaces. It is applied to one side of the backing material. The adhesive used in pressure-sensitive tape is designed to create a bond when slight pressure is applied, making it stick to surfaces instantly.

Release Liner: In many pressure-sensitive tapes, especially those on rolls, a release liner is applied to cover the adhesive side. This liner is typically made of paper or plastic and is removed before applying the tape.

The numerical values that we test under restrictive conditions are basic indication of tape performance and feature descriptions of each tape. Please utilize them when you study which tape you need to use by the applications, conditions, adherends, and so on for your reference.

Tape structure

-Single sided tape

-Double sided tape

-Double sided tape

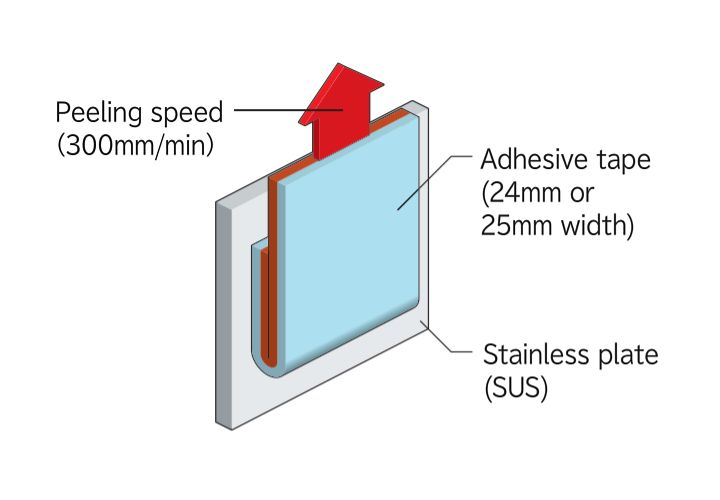

Explanation of test method

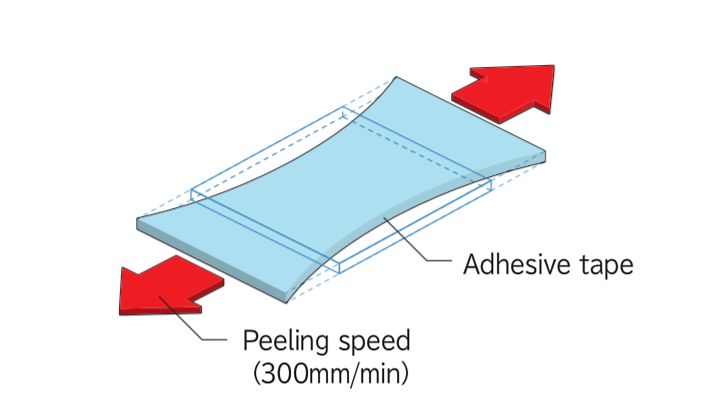

-Adhesion

Force that is generated by peeling off the tape from stainless plate to the angle of 180° (or 90°).

It is the most common property to make a selection of tape. The value of adhesion varies by temperature,adherend (material the tape to be applied to), applying condition.

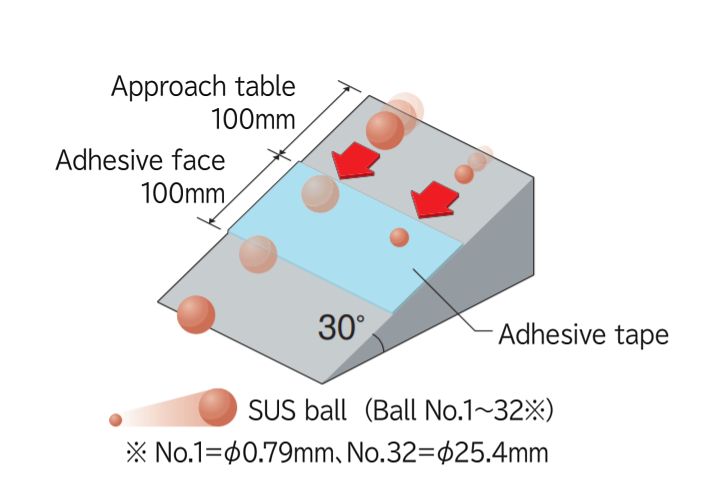

-Tack

Force that is needed to adhere to adherend by light force. The measurement is done by setting adhesive tape with the adhesive face upward to the inclined plate with the angle of 30° (or 15°), and measure the maximum size of SUS ball, which stops completely within the adhesive face. This is the effective method to find initial adhesion or adhesion at low temperatures.

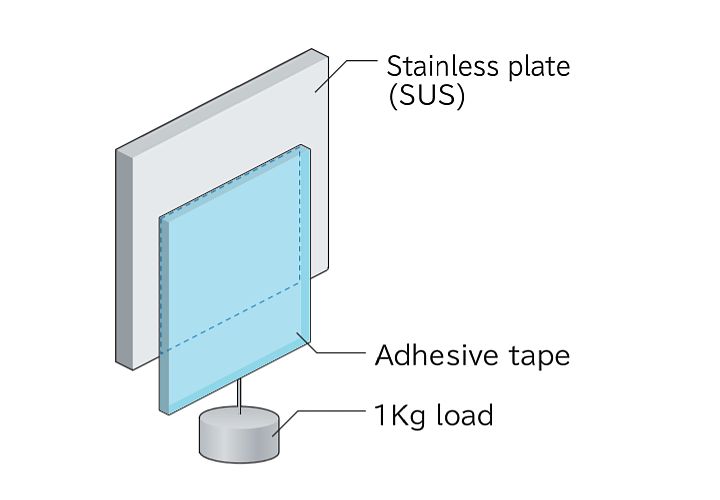

-Holding power

Resistant force of tape, which is applied to stainless plate with static load (typically 1kg) attached to the length direction.Distance (mm) of displacement after 24 hours or time (min.) elapsed until the tape drops from the stainless plate.

-Tensile strength

Force when tape is pulled from both ends and breaks. As larger the value is, the higher the strength of the backing material.

-Elongation

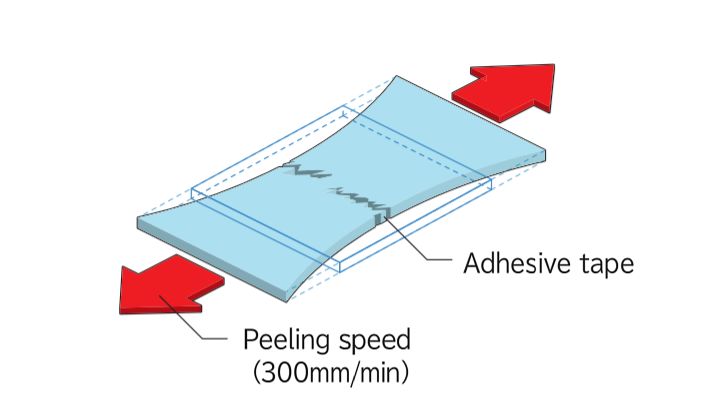

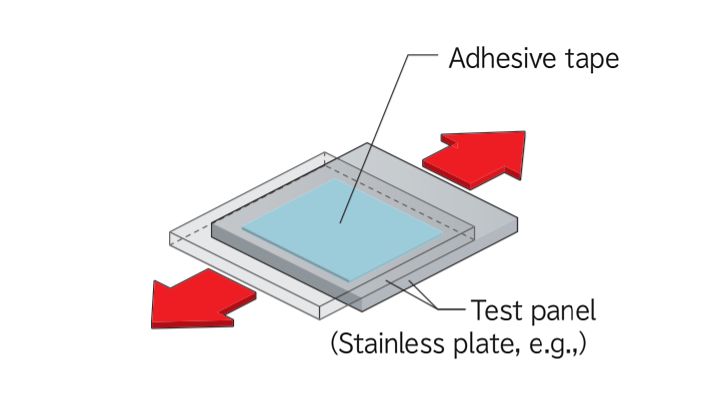

-Shear adhesion (only relevant to double sided tape)

Force when double sided tape is sandwiched with two test panels and pulled from both ends until break.

Post time: Aug-28-2023