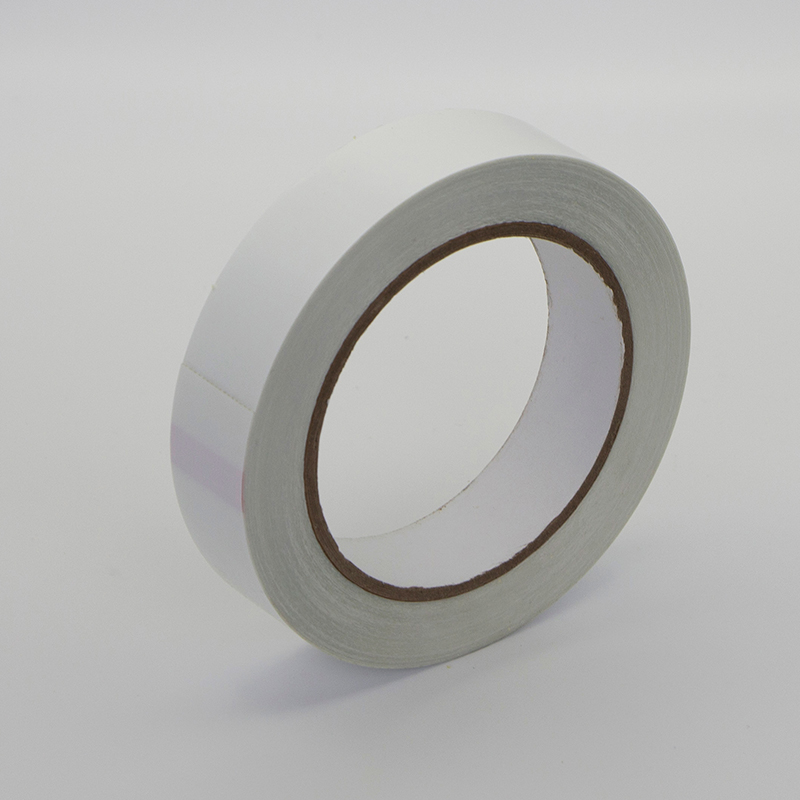

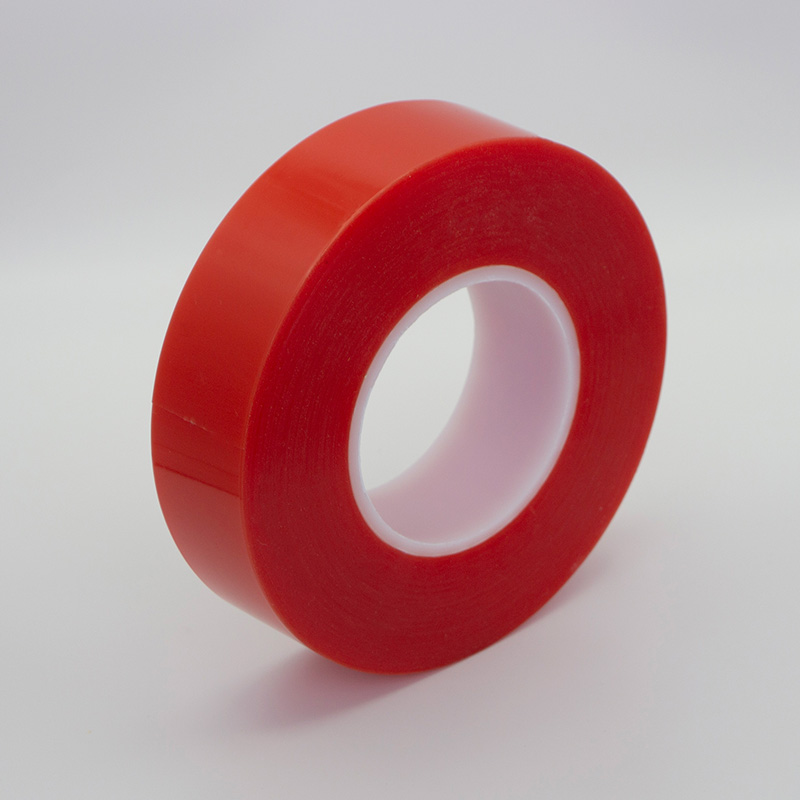

JD6221RF FIRE-RETARDANT DOUBLE- SIDED FILAMENT TAPE

Properties

|

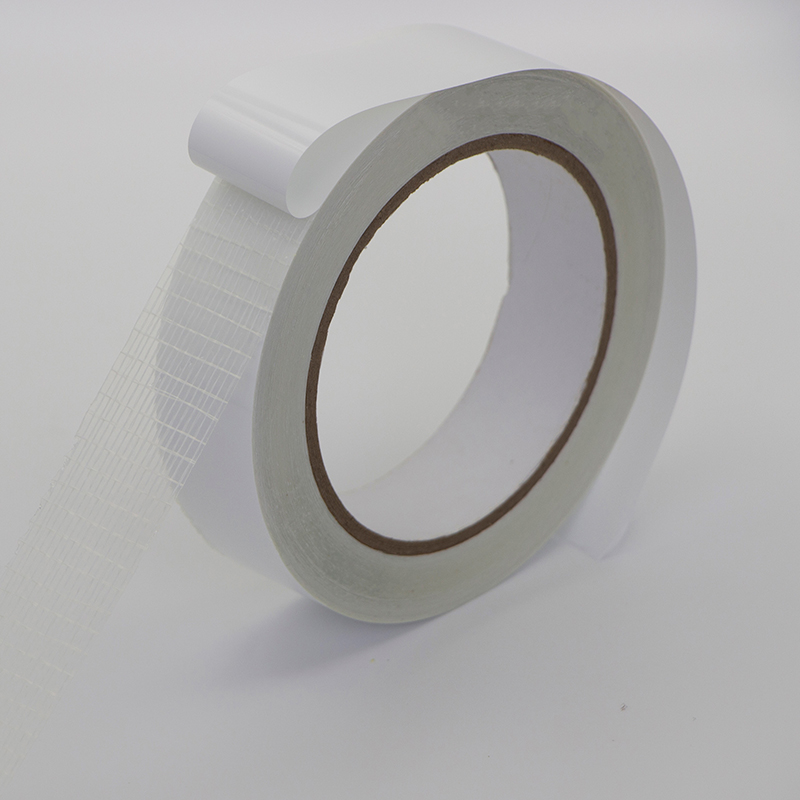

Backing |

Glass fiber |

|

Adhesive Type |

FR Acrylic |

|

Color |

Clear with filaments |

|

Thickness (μm) |

150 |

|

Initial Tac |

12# |

|

Holding Power |

>12h |

|

Adhesion to Steel |

10N/25mm |

|

Breaking Strength |

500N/25mm |

|

Elongation |

6% |

|

Flame Retardancy |

V0 |

Applications

● Sealing strip of doors, windows where flame retardant feature.

● Sporting Mat.

● Bonding in aircraft cabin interior.

● Assemblies in trains.

● Marine applications.

Self Time & Storage

Store in a clean, dry place. Temperature of 4-26°C and 40 to 50% relative humidity are recommended. To obtain best performance, use this product within 18 months from date of manufacture.

● Excellent adhesion to a variety of corrugated and solid board surfaces.

● Excellent fire-retardant properties.

● High ageing resistance.

● Tear-resistant.

● Ensure that the surface of the adherend is clean from dirt, dust, oils, etc. before applying the tape. This will help to achieve better adhesion.

● Apply sufficient pressure on the tape after application to ensure proper adhesion.

● Store the tape in a cool, dark place, and avoid exposure to heating agents like direct sunlight and heaters. This will help maintain the quality of the tape.

● Do not use the tape directly on skin unless it is specifically designed for that purpose. Using tape not intended for skin may cause a rash or leave adhesive residue.

● Carefully select the appropriate tape to avoid adhesive residue or contamination on the adherends. Ensure that the tape is suitable for the specific requirements of your application.

● Consult with the manufacturer if you have any special or unique application needs. They can provide guidance based on their expertise.

● The values provided are based on measurements, but they are not guaranteed by the manufacturer.

● Confirm the production lead-time with the manufacturer as some products may require longer processing time.

● The product specifications may change without prior notice, so it is essential to stay updated and communicate with the manufacturer for any changes.

● Exercise caution when using the tape, as the manufacturer does not hold any liabilities for damage that may result from its use.

● If you have any further questions or need additional assistance, please feel free to ask.