JD560RS GLASS CLOTH ELECTRICAL TAPE

Properties

|

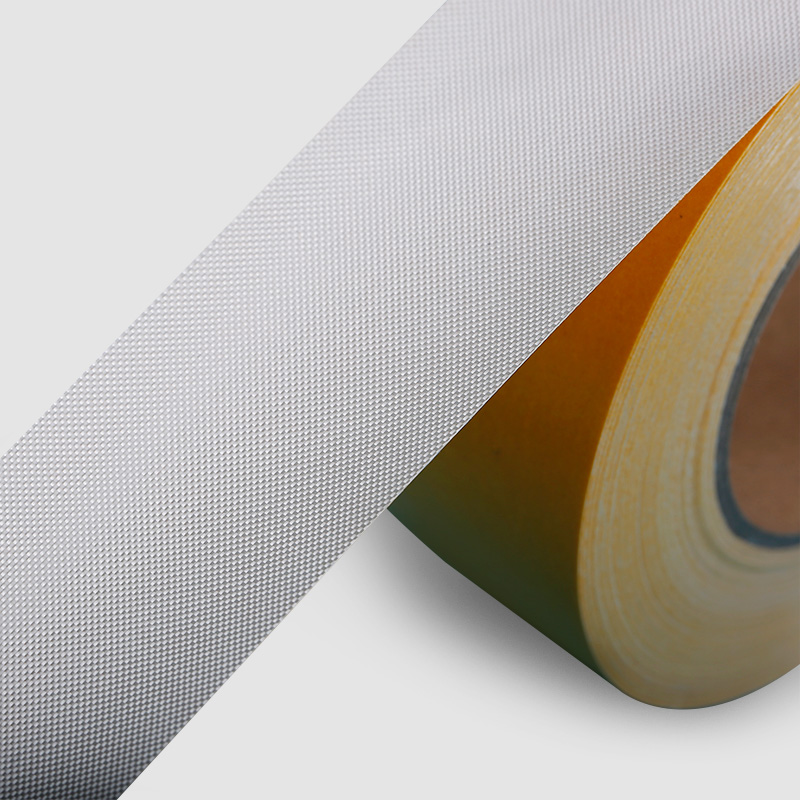

Backing material |

Fiberglass Cloth |

|

Type of adhesive |

Silicone |

|

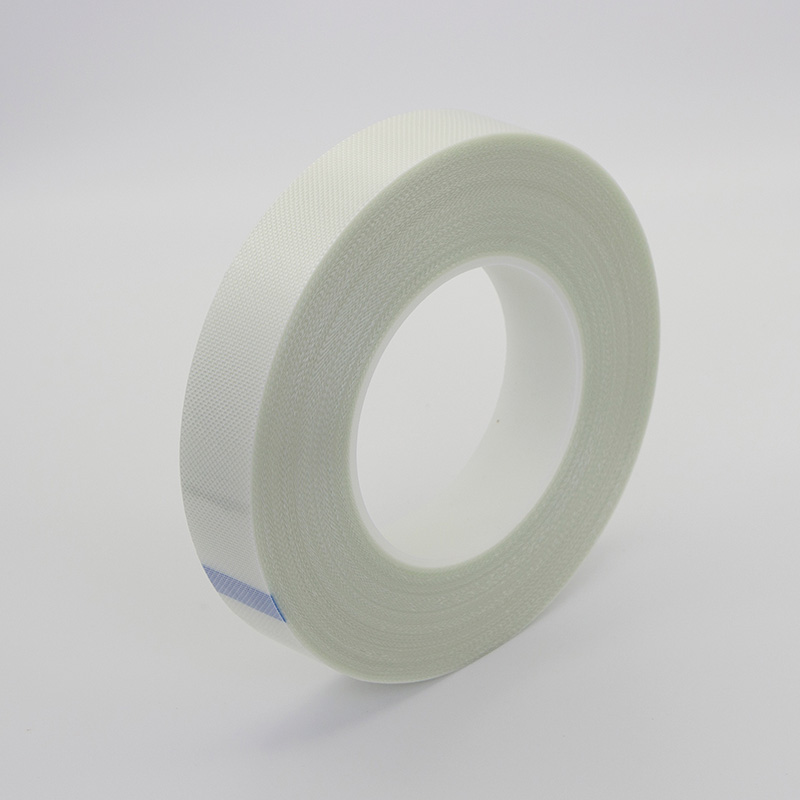

Total thickness |

180 μm |

|

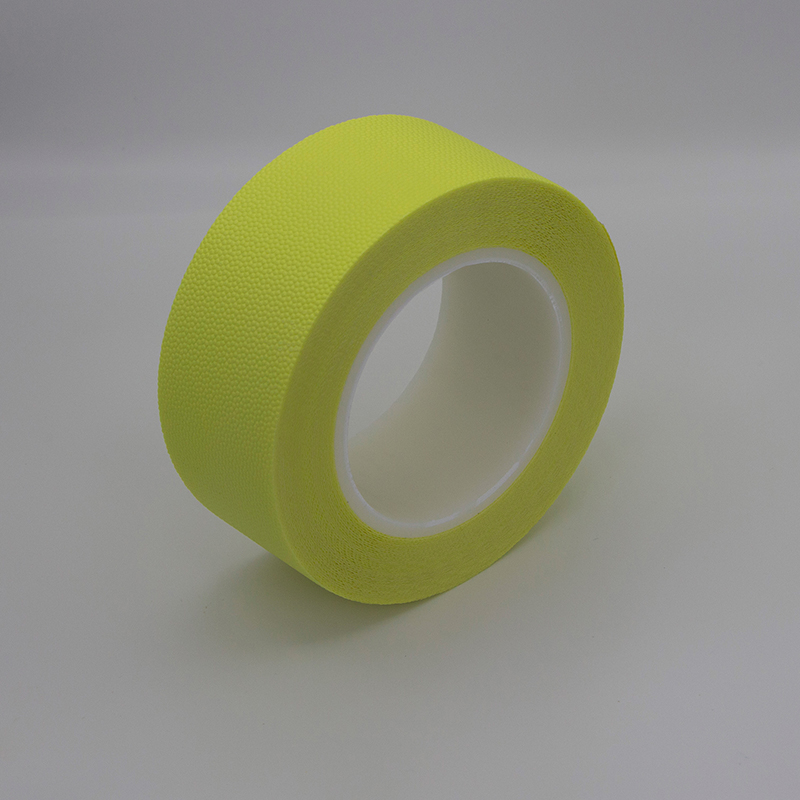

Color |

White |

|

Breaking Strength |

500 N/inch |

|

Elongation |

5% |

|

Adhesion to Steel 90° |

7.5 N/inch |

|

Dielectric Breakdown |

3000V |

|

Temperature Class |

180˚C (H) |

Applications

Used for various coil/transformer and motor applications, high-temperature coil insulation wrapping, wire harness winding, and splicing.

Self Time & Storage

When stored under controlled humidity conditions (10°C to 27°C and relative humidity <75%), the shelf life of this product is 5 years from the date of manufacture.

● At extreme temperatures ranging from low temperatures to 200 ºC.

● Non–corrosive, solvent resistant, thermosetting silicone adhesive.

● Resists rotting and shrinking after extended use in a variety of environments.

● Use as coil cover, anchor, banding, core layer and crossover insulation.

● Before applying the tape, ensure that the surface of the adherend is free from dirt, dust, oils, and other contaminants.

● Apply sufficient pressure on the tape after application to ensure proper adhesion.

● Store the tape in a cool and dark place, avoiding exposure to heating agents such as direct sunlight and heaters. This will help maintain the quality of the tape.

● Do not use the tape directly on skin unless it is specifically designed for that purpose. Otherwise, it may cause a rash or leave adhesive residue.

● Carefully select the appropriate tape to avoid adhesive residue or contamination on the adherends. Consider the specific requirements of your application.

● Consult with the manufacturer if you have any special or unique application needs. They can provide guidance based on their expertise.

● The values described have been measured, but they are not guaranteed by the manufacturer.

● Confirm the production lead-time with the manufacturer, as some products may have longer processing times.

● The product specifications may change without prior notice, so it is important to stay updated and communicate with the manufacturer.

● Use caution when using the tape, as the manufacturer does not hold any liabilities for damage that may occur from its use.